|

Towel

Banding Machines

We provide banding machines that automatically apply

bands to folded towels. These units can easily be

integrated with existing folding and stacking systems.

The type of bands and the manner in which they are

applied to the towels are tailored to the individual

needs of the manufacturer.

Bands can be applied at various positions along the

width of the towels. They can be applied around the

towels or on one side. Bands can be plain or adhesive,

and of various widths, offering complete flexibility.

Please contact Brintech for your

specific banding needs

|

|

LETS

Line Efficiency Tracking System

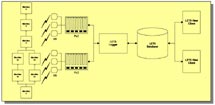

LETS (Line Efficiency Tracking System) is a client/server based software system that enables the monitoring of production and packaging lines in order to achieve maximum output with minimal downtime.

LETS interfaces with manufacturers' equipment on their production lines to gather production and runtime relevant data. Numerous reports are available to allow review and analysis to be achieved in a concise and organized fashion. Using these reports, manufacturers can quickly and easily determine problem areas in their lines.

Using LETS, manufacturers increase their production efficiency, flexibility, and capacity, reducing downtime and operating costs, and achieving regulatory compliance. A 6% to 10% increase in production is generally achieved.

LETS can be used for the following:

· Pinpoint machine inefficiencies and problem areas

· Track discrete events

· Provide detailed production and scrap counts per machine/line/area

· Assist in product run scheduling

· Capture analog data during critical production times

· Keep a maintenance calendar for machines based on operating time or cycles

LETS can display the current status of each line component while it collects production data. The stored data is available in a variety of user-selected options and reporting formats.

LETS is designed to be integrated with existing control systems such that any available process information can easily be collected and stored in

LETS.

Contact Brintech to find out how LETS can benefit your operation |

|

| |

|